NASA

Johnson Space Center

As an intern at NASA's Habitability Design Department, my team's primary project was the Space Exploration Vehicle Gen II Rover (Mars Rover), which is a modification of the Gen IA and Gen IB Lunar Rover Prototypes.

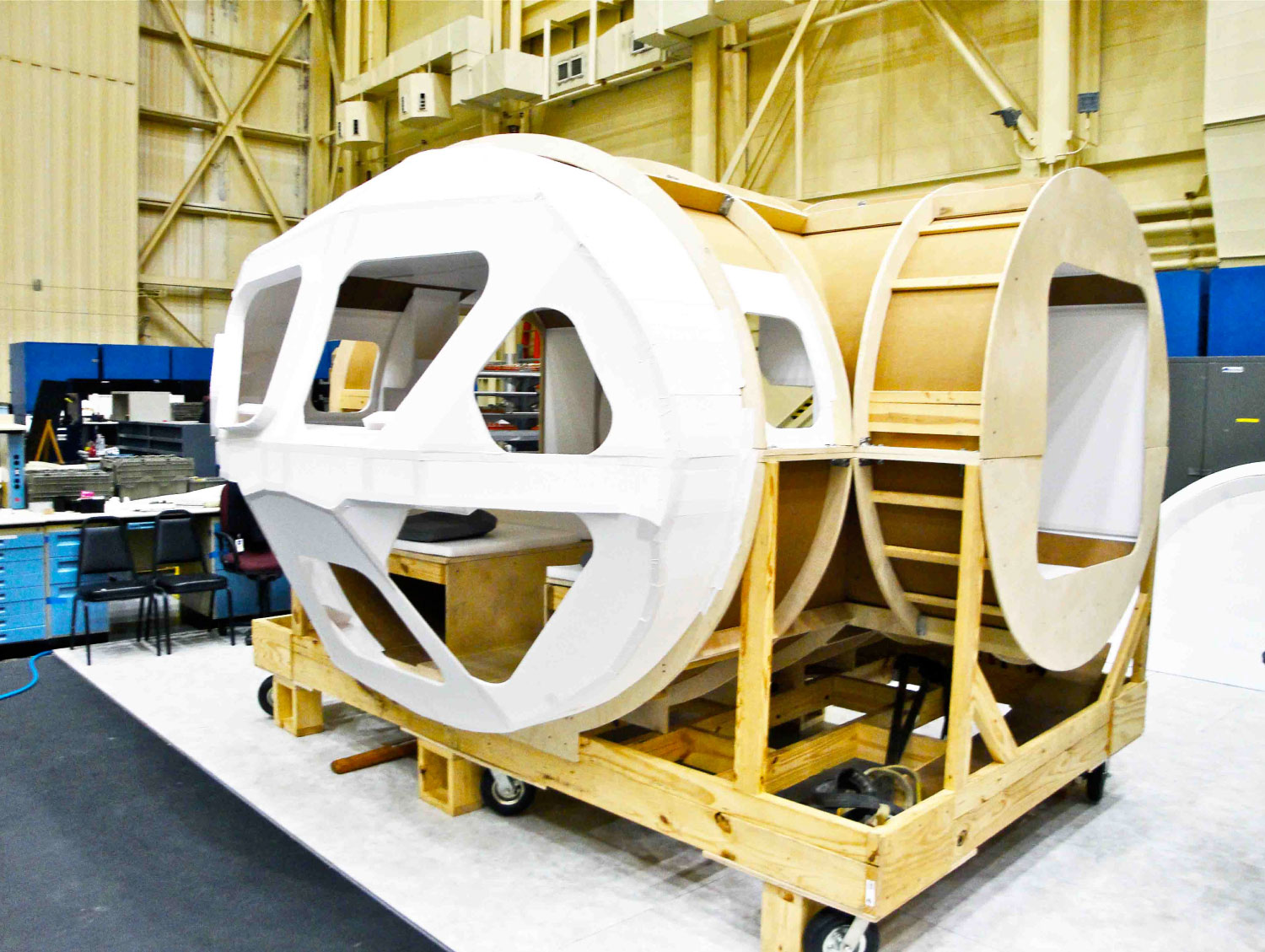

Create a full-scale prototype of the interior of the Gen II Rover for testing by astronauts and HDC personnel, in addition to small-scale models for nose frame and aft enclosure design iterations.

The full-scale mock up was an important tool in helping the team decide on the shape and placement of the rover’s interior components in order to optimize the habitability and operability of the vehicle. We constructed and installed seats, storage compartments, and other necessary components of the rover’s interior.

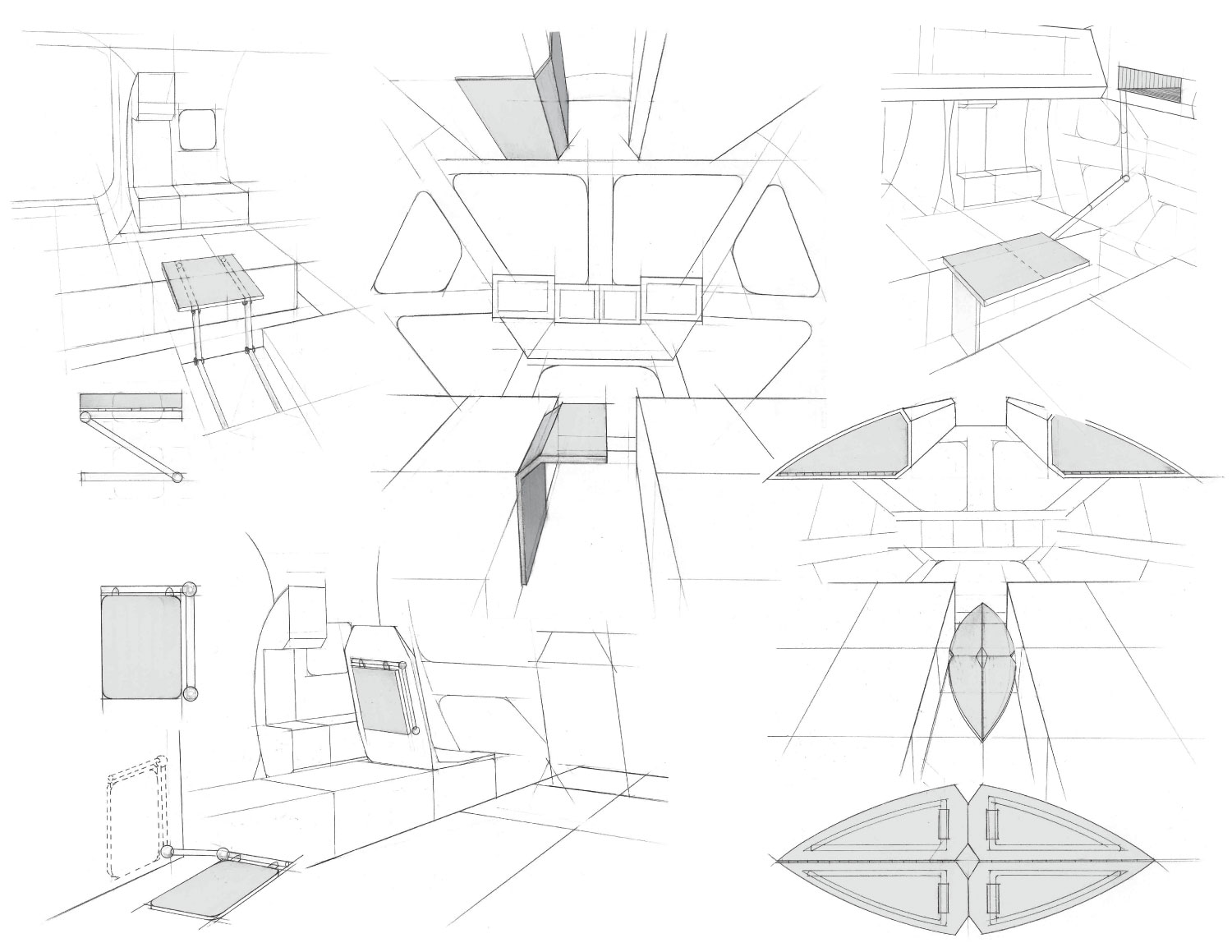

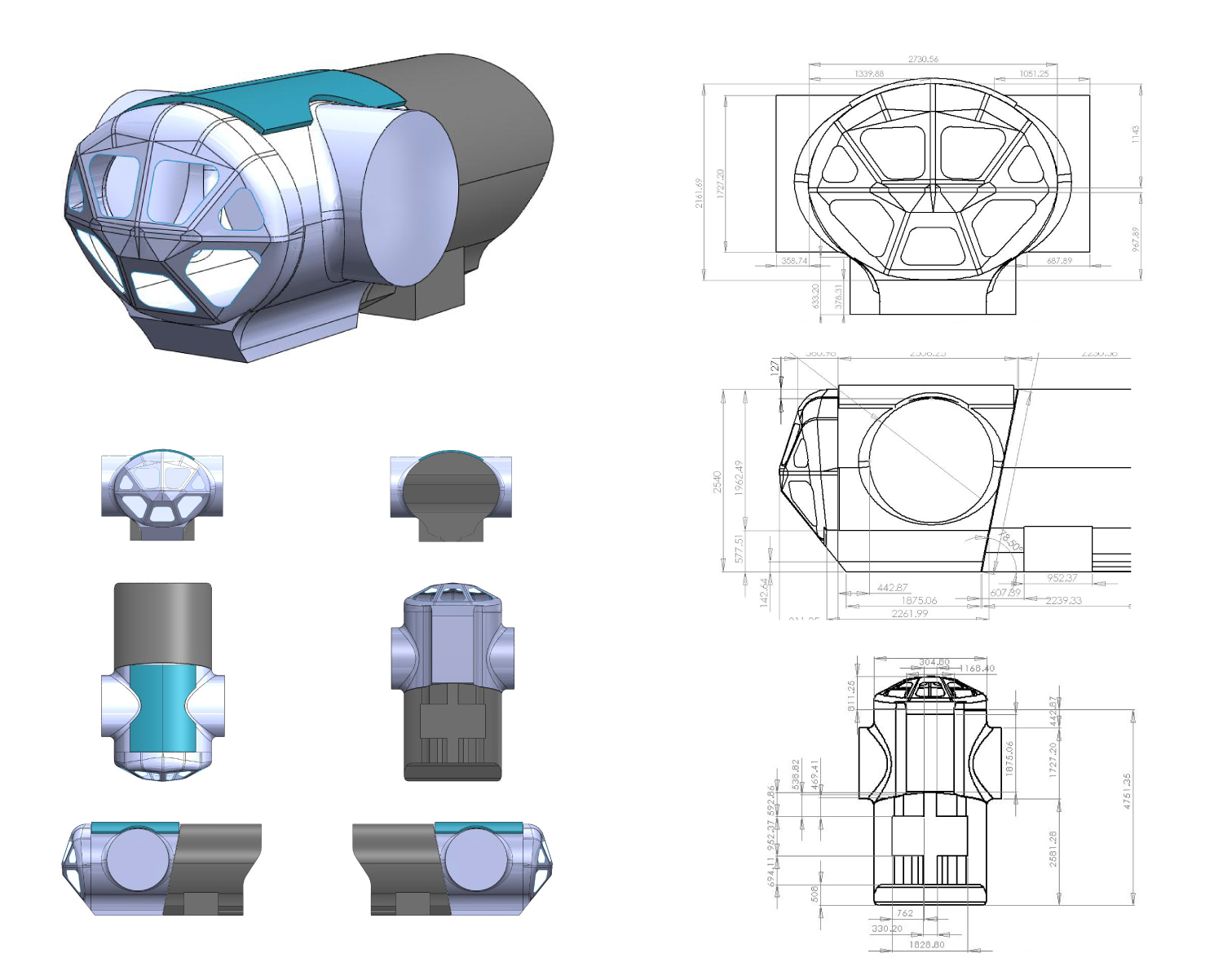

We worked from a CAD and orthographic drawing to create small-scale fin models of the rover. We designed nose frame and aft enclosure iterations to be easily interchangeable on the models.

The full-scale mock up was an important tool in helping the team decide on the shape and placement of the rover’s interior components in order to optimize the habitability and operability of the vehicle. We constructed and installed seats, storage compartments, and other necessary components of the rover’s interior. Mock ups were created out of wood and foam core.

After installing all components, the prototype was tested by astronauts and HDC personnel. We then made appropriate changes to the interior based on feedback from the team.

While outfitting the interior of the rover, our team was tasked to come up with concepts for an eating / working surface for the rover. Because of limited space inside the rover, I thought of ways to incorporate the eating / working surface into the existing architecture of the rover in order to maximize living space.

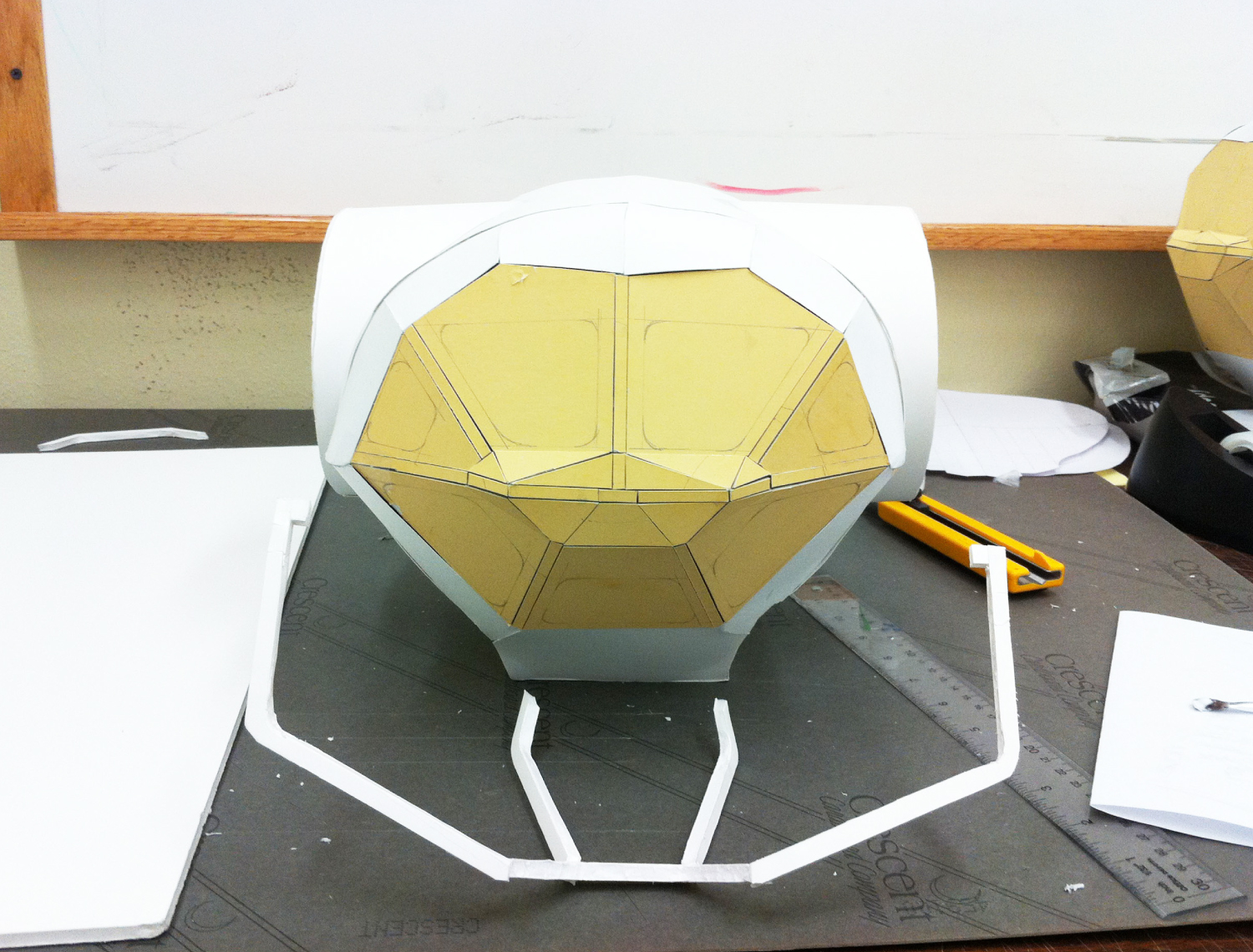

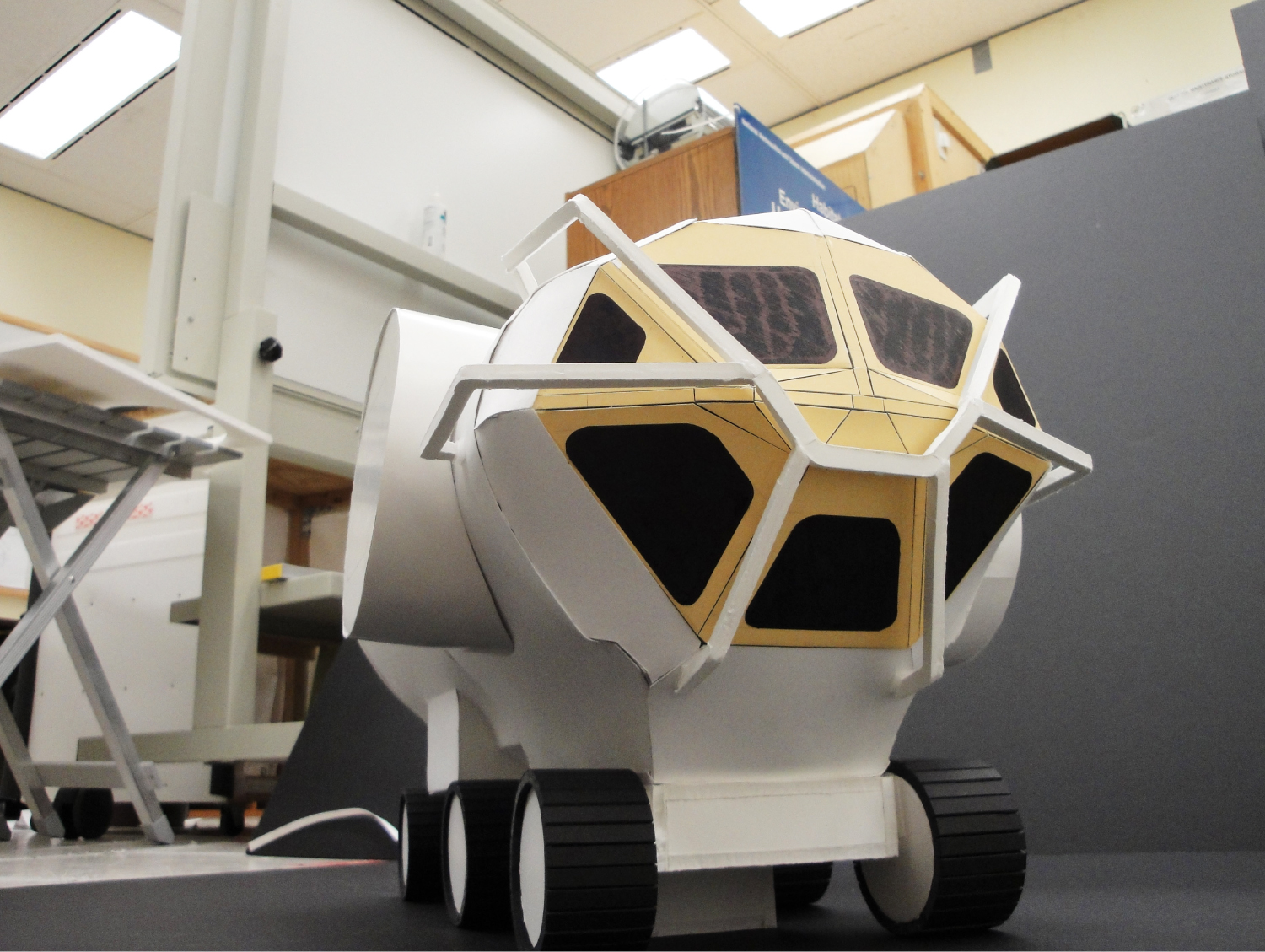

In addition to the full scale mock up of the rover’s interior, we made three small scale models of the rover’s exterior. These models were to be used by the HDC team as a way to mock up designs for the rover’s nose frame and aft enclosure.

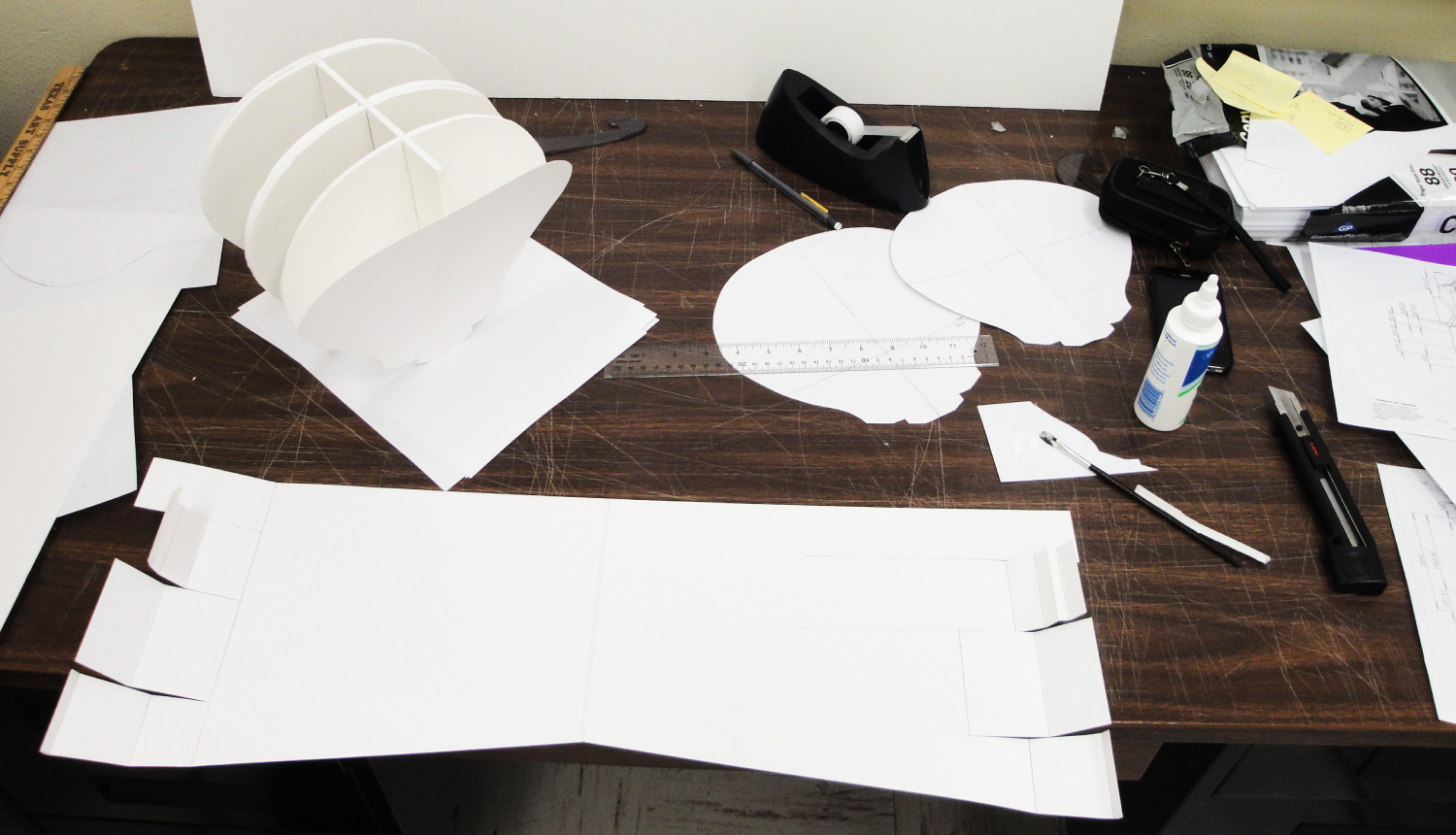

We worked from a CAD model and orthographic drawings to create templates for our models. The cross sections of the rover were transferred to foam core to create three uniform fin models. We then wrapped each fin model in paper that was carefully cut to fit the rover’s curvature.

All parts were made easy to disassemble and interchangeable in order for the team to easily construct different exterior design solutions.

Copyright © 2008 – Stephanie DelVecchio Glaze All Rights Reserved